Image Source: FreeImages

Introduction to Digital Twins

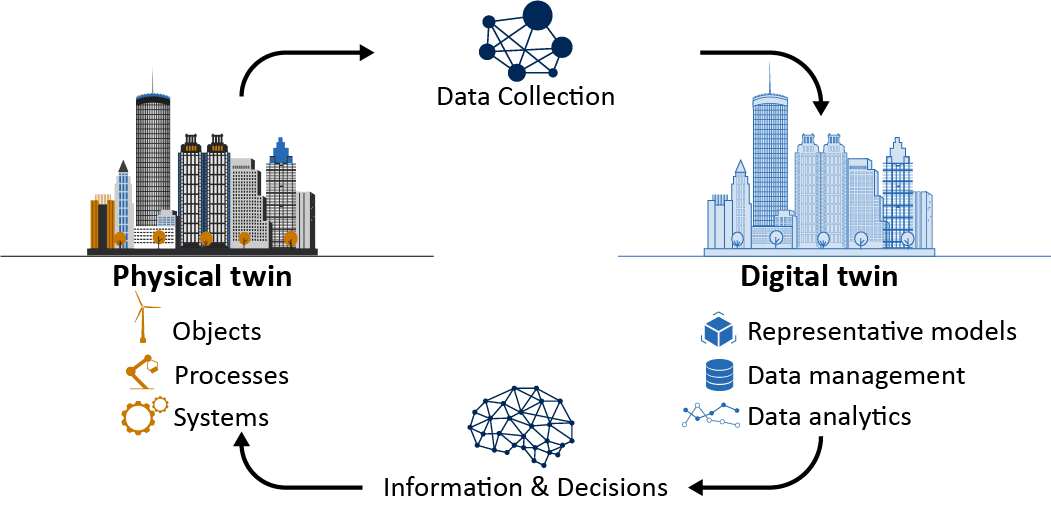

In the rapidly evolving world of technology, the power of digital twins has emerged as a game-changer, revolutionizing the way businesses approach process simulation and optimization. A digital twin is a virtual representation of a physical asset, process, or system that enables real-time monitoring, analysis, and prediction of its performance.

Image source: Statetech

By creating a digital counterpart of a real-world entity, organizations can gain unprecedented insights, make informed decisions, and drive continuous improvement.

Understanding the Concept of Process Simulation and Optimisation

Process simulation is the act of creating a digital model that mimics the behavior and performance of a real-world process or system. This allows businesses to test, analyze, and optimize their operations without disrupting the actual production environment.

Image source: Arrival 3D

Process optimization, on the other hand, involves the systematic improvement of these processes to enhance efficiency, productivity, and profitability.

The Benefits of Digital Twins in Process Simulation and Optimisation

The integration of digital twins into process simulation and optimization offers a wealth of advantages. By creating a virtual representation of a physical system, organizations can:

- Enhance Visibility and Transparency: Digital twins provide a comprehensive, real-time view of the entire process, allowing for better understanding and identification of bottlenecks, inefficiencies, and opportunities for improvement.

- Improve Decision-Making: With the ability to simulate and test various scenarios, businesses can make more informed, data-driven decisions that lead to better outcomes and reduced risks.

- Increase Efficiency and Productivity: Digital twins enable the optimization of processes, leading to increased throughput, reduced waste, and enhanced resource utilization.

- Reduce Costs and Downtime: By identifying and addressing issues in the virtual environment, organizations can avoid costly disruptions and unplanned downtime in the physical world.

- Foster Innovation: The insights gained from digital twins can inspire the development of new products, services, or processes, driving continuous innovation within the organization.

Real-World Applications of Digital Twins in Different Industries

Digital twins have found widespread application across various industries, each with its unique challenges and opportunities. In the manufacturing sector, digital twins are used to simulate production lines, optimize equipment maintenance, and predict failures.

Image source: 12D synergy

In the energy industry, they are employed to model power generation systems, optimize grid operations, and forecast demand. In the healthcare domain, digital twins are utilized to simulate patient outcomes, test new medical devices, and personalize treatment plans.

Case Studies Showcasing the Success of Digital Twins in Process Optimisation

- Optimizing a Chemical Plant’s Production Process: A leading chemical manufacturer implemented a digital twin of its production facility, which enabled them to simulate different operating conditions, identify bottlenecks, and optimize the process. As a result, they achieved a 15% increase in throughput and a 20% reduction in energy consumption.

Image source: Spiceworks - Improving Efficiency in an Automotive Assembly Line: An automotive OEM leveraged digital twins to model its assembly line, allowing it to simulate various scenarios and optimize workflow. This led to a 12% reduction in cycle time, a 9% increase in output, and a significant decrease in quality-related issues.

- Enhancing Oil and Gas Reservoir Management: An oil and gas company developed a digital twin of its reservoir, which helped them simulate different production strategies, predict fluid flow, and optimize well placement. This resulted in a 7% increase in oil recovery and a 9% reduction in operating costs.

Implementing Digital Twins in Your Business

Adopting digital twins in your business involves a strategic and methodical approach. Key steps include:

- Identify the Right Use Cases: Determine the specific processes or systems that would benefit most from digital twin technology, considering factors such as complexity, the potential for optimization, and impact on the business.

- Gather and Integrate Data: Collect and integrate data from various sources, including sensors, historical records, and enterprise systems, to create a comprehensive digital representation of the physical asset or process.

- Develop the Digital Twin: Leverage advanced simulation and modeling tools to build the digital twin, ensuring it accurately reflects the behavior and performance of the real-world counterpart.

- Implement and Iterate: Deploy the digital twin in a controlled environment, continuously monitor its performance, and make iterative improvements to enhance its accuracy and predictive capabilities.

- Empower Decision-Making: Leverage the insights and analytics generated by the digital twin to make informed, data-driven decisions that drive process optimization and business growth.

Challenges and Considerations in Adopting Digital Twins

While the benefits of digital twins are compelling, organizations may face several challenges in their adoption and implementation. These include:

- Data Quality and Integration: Ensuring the accuracy, completeness, and timeliness of data used to build the digital twin is crucial for its effectiveness.

- Technological Complexity: Developing and maintaining a robust digital twin requires advanced simulation and modelling capabilities, as well as integration with various enterprise systems.

- Organisational Readiness: Successful implementation of digital twins often requires a cultural shift, with employees embracing new technologies and processes.

- Cybersecurity and Data Privacy: Organisations must address the potential risks associated with the digital twin, such as data breaches and cyber threats, to ensure the protection of sensitive information.

The Future of Digital Twins in Process Simulation and Optimisation

As technology continues to evolve, the role of digital twins in process simulation and optimisation is poised to expand. Emerging trends, such as the integration of artificial intelligence (AI) and machine learning (ML), will enhance the predictive capabilities of digital twins, enabling more accurate forecasting and proactive decision-making. Additionally, the proliferation of the Internet of Things (IoT) and advancements in edge computing will further strengthen the real-time monitoring and responsiveness of digital twins, driving continuous process improvement.

Tools and Technologies for Developing and Managing Digital Twins

Numerous tools and technologies are available to support the development and management of digital twins. These include:

- Simulation and Modelling Software: Tools like ANSYS, Dassault Systèmes, and Siemens PLM Software provide advanced simulation and modeling capabilities for creating digital twins.

- IoT Platforms: IoT platforms, such as Microsoft Azure IoT, AWS IoT Core, and PTC ThingWorx, enable the integration of real-time sensor data and the management of digital twins.

- Data Analytics and Visualisation: Tools like Tableau, Power BI, and Qlik Sense offer robust data analytics and visualization capabilities to extract insights from digital twin data.

- Artificial Intelligence and Machine Learning: AI and ML algorithms, such as those provided by TensorFlow, PyTorch, and Azure Machine Learning, can be integrated into digital twins to enhance their predictive and optimization capabilities.

Conclusion: Embracing the Power of Digital Twins for Enhanced Process Efficiency

In conclusion, the power of digital twins has revolutionized the way businesses approach process simulation and optimization. By creating virtual representations of physical assets and systems, organizations can gain unprecedented insights, make informed decisions, and drive continuous improvement.

As technology continues to evolve, the future of digital twins in process optimization is poised to be even more transformative, empowering businesses to achieve new levels of efficiency, productivity, and innovation.

Hire JBM Digital to optimize and take your business to the next level today. Our team of experts specializes in leveraging the power of digital twins to enhance process simulation and optimization, driving tangible results for our clients.

Contact us now to learn how we can help your organization unlock its full potential.

Recent Comments